FLUOROSHIELD® is a PFA-based dispersion (wet spray) coating. These coatings use 100% melt processible fluoropolymers spray-applied to the substrate and baked after each successive layer. Fluoroshield® offers near universal chemical resistance, superior resistance to mechanical damage, and performs well at elevated temperatures. Fluoroshield® is field repairable and can be applied to most metals, except those alloys which contain a high copper content.

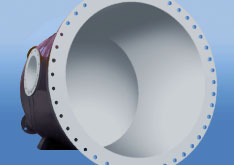

GSC-C

![]() FLUOROSHIELD® GSC-C utilizes a proprietary fusion layer between the metal substrate and the coating for a total thickness from 40-60 mils. This intermediate layer provides the coating system with bond strength well in excess of that required to withstand full vacuum.

FLUOROSHIELD® GSC-C utilizes a proprietary fusion layer between the metal substrate and the coating for a total thickness from 40-60 mils. This intermediate layer provides the coating system with bond strength well in excess of that required to withstand full vacuum.

GSC-CS

![]() The coating in FLUOROSHIELD® GSC-CS is filled with an intermediate layer of activated carbon which greatly enhances performance and longevity in vapor andliquid applications. This coating has a total thickness of 60 mils.

The coating in FLUOROSHIELD® GSC-CS is filled with an intermediate layer of activated carbon which greatly enhances performance and longevity in vapor andliquid applications. This coating has a total thickness of 60 mils.

GSC-M

![]() FLUOROSHIELD® GSC-M is reinforced with a stainless wire mesh which is welded to the metal substrate prior to the coating; the fluoropolymer then flows in and around the wire mesh, resulting in bond strength greater than the polymer’s tear strength and a thickness from 60-100 mils.

FLUOROSHIELD® GSC-M is reinforced with a stainless wire mesh which is welded to the metal substrate prior to the coating; the fluoropolymer then flows in and around the wire mesh, resulting in bond strength greater than the polymer’s tear strength and a thickness from 60-100 mils.

GSC-MS

![]() FLUOROSHIELD® GSC-MS combines the properties of both the GSC-CS and the GSC-M coatings in order to achieve the best of both worlds. This coating is available in a total thickness from 80-100 mils.

FLUOROSHIELD® GSC-MS combines the properties of both the GSC-CS and the GSC-M coatings in order to achieve the best of both worlds. This coating is available in a total thickness from 80-100 mils.

GSC-CE

![]() FLUOROSHIELD ® GSC-CE takes advantage of a static-dissipating graphite barrier. This layer can be applied to GSC-C, GSC-M, and GSC-MS systems.

FLUOROSHIELD ® GSC-CE takes advantage of a static-dissipating graphite barrier. This layer can be applied to GSC-C, GSC-M, and GSC-MS systems.

why choose Fluoroshield®?

With increasing demands for improved chemical, thermal and mechanical properties of corrosion protection systems, development of new materials has become necessary for both process plant and pipework systems.

In order to meet these technical requirements and yet remain cost effective, FLUOROSHIELD® coating was developed-a unique coating material for corrosion protection of vessels, tanks and ancillary equipment used throughout the chemical processing industries.

The main benefits of the coating, which can be applied up to 100 mils thick, are universal chemical resistance (0 to 14pH), operating temperature range of -310°F to +482°F* and full vacuum operation.

The FLUOROSHIELDŽ Process

The outstanding results achieved with FLUOROSHIELD® coating is due to the type of polymer employed and the specific method of application. The required coating thickness results by building up successive layers of polymer and baking the part after each coat. In this way a pore-free coating, which passes a 10kV spark test, is achieved.

Metal Specification for FLUOROSHIELDŽ Coatings

A number of prerequisites have to be fulfilled to achieve a perfect corrosion resistant coating. The most important considerations are non-porous, continuous welds, radiused edges and the capability of the substrate to withstand 750°F. More detailed information can be obtained by requesting a copy of our metal specifications leaflet.

Chemical Properties

The selection of materials for chemical process equipment has never been a straightforward exercise. The ever increasing need for versatility (e.g. chemical resistance, temperature, pressure, and vacuum capability as well as the ability to resist thermal shock and mechanical damage) at a reasonable price has presented material engineers with an even greater challenge. More and more companies are asking for multi-purpose plants, capable of trouble-free operation in any future unspecified chemical environment (i.e. plants offering universal chemical inertness).

FLUOROSHIELD® coatings employ fully fluorinated polymers capable of operation at temperatures up to 482°F* while ensuring the necessary level of chemical resistance for multipurpose plants. Only a few chemicals can attack the structure of FLUOROSHIELD® coatings in the upper temperature range. They are elemental fluorine and molten alkali metals. As these are the only restrictions there is no need for a chemical reference list.

| Property | ASTM | UNITS | FLUOROSHIELD® |

| Density | D -1505 | #/in_ | .074 |

| Operating Temperature Range | ºF | -310 to +482* | |

| Linear Coefficeint of Thermal Expansion |

D - 696 | x10-s ºF | 5.4 |

| Thermal Cunductivity at 74% | BTU/Hr/Sq Ft ºF/in | 1.5 | |

| Combustability | Non-combustable | ||

| Water Absorption | D - 50 | % | <0.03 |

| Tear Strength | D - 1922 | g/mil | 40-70 |

| Tear Elongation | D - 638 | % | 300 |

| Shore Hardness | D - 785 | Shore D | 57-65 |

| Oxygen Index | % | >95 | |

| Tensile Strength | D - 882 | lbs/in2 | 4000-7000 |

| Surface Resistivity | D - 257 | OHM/in2 | 1017 |

| Vacuum | Full Vacuum Capacity | ||

Field Repair Capability

Should mechanical damage occur during use, the coating can be repaired on site. As FLUOROSHIELD® coatings “melt flow” at elevated temperatures, reliable repairs can be achieved quickly, reducing expensive down-time cost.

Quality Control

Quality control of the coating process entails continuous checking of raw materials as well as regular testing and improvement of production methods. Proper quality control of a coating can only be achieved by way of destructive testing. In order to achieve top quality, test specimens of FLUROSHIELD® coatings are applied, normally on the outside of the part. This is then subjected to a peel test.

After completing the coating process a 10kV spark test ensures a pinhole-free coating. The finished part is then subjected to a careful visual inspection.